GDT > Projects > Northwest Rail > RTD Peak Service Study

RTD Peak Service Study

In 2022, the RTD Board of Directors authorized the study to respond to stakeholder input on how RTD might complete its 2004 FasTracks Plan by assessing an initial commuter rail service in the Northwest Corridor. The study advances the concept brought forward from local stakeholders and RTD staff with a specific focus on developing a “common set of facts” to inform the RTD Board of possible next steps.

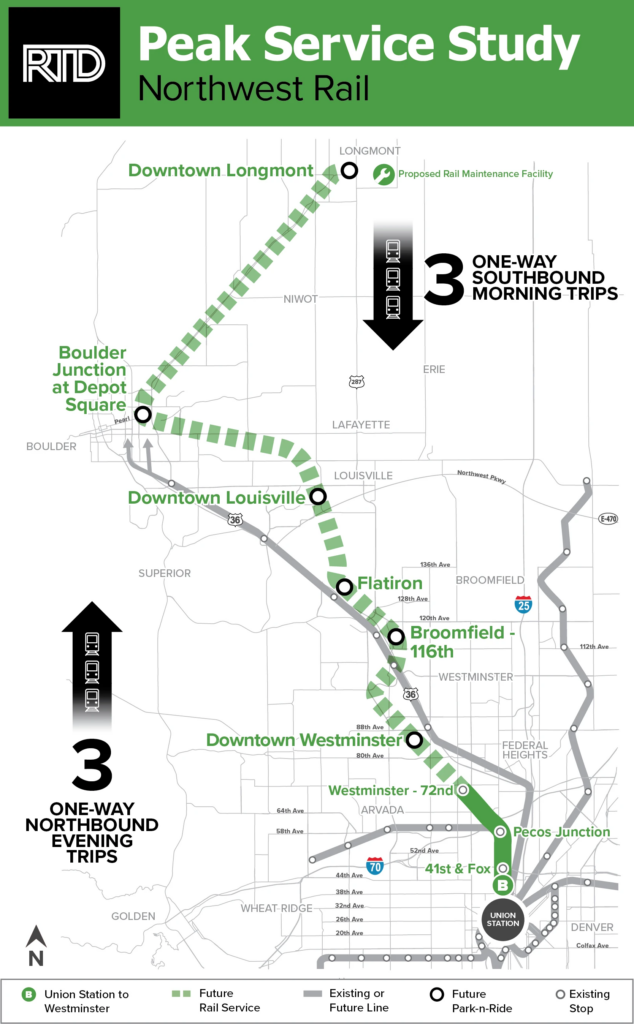

The project team began the study with the basic service concept defined by stakeholders and the Board. The peak service concept is three trains in the morning from Longmont to Denver Union Station stopping at all stations and three trains back in the afternoon. The study then went on to identify corridor and regulatory challenges and constraints, infrastructure requirements, fleet (train vehicle) options, station site plans, platform configurations, concept designs, and the range of costs, benefits, and impacts of providing the service.

Finally next steps, such as how to collaborate with the Front Range Passenger Rail District were identified.

How would the peak service concept work?

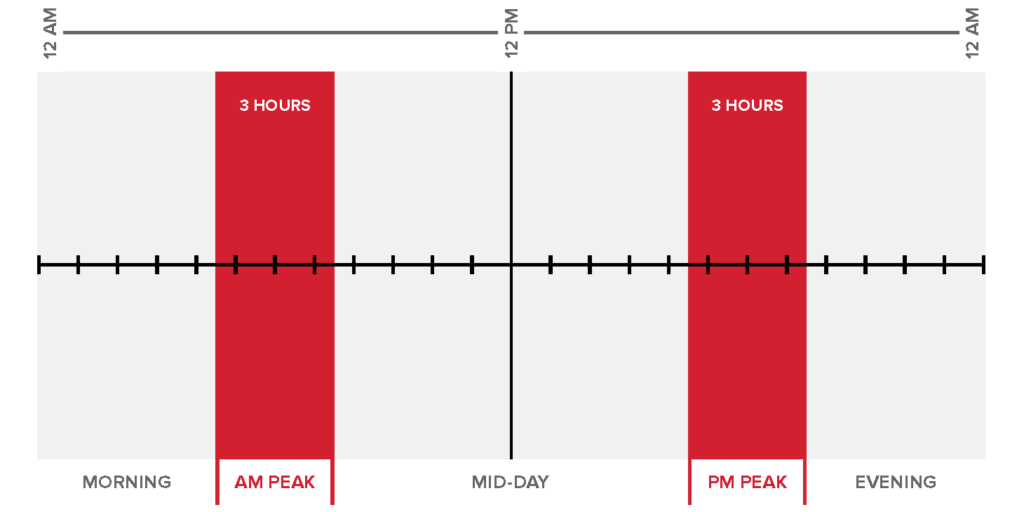

The basic concept comprises of RTD operating three peak services at 30-minute intervals from Longmont to Denver Union Station (DUS) in the morning with return trips in the evening. The trains would use BNSF tracks from Longmont to Westminster and then complete their journey into DUS using RTD’s existing B Line commuter rail tracks. During the day the trains would lay over at new sidings at Westminster, substituting for current B Line services on both their trips in and out of DUS.

Journey time from Longmont to DUS is planned to be 65 minutes, plus or minus two minutes which is competitive with driving.

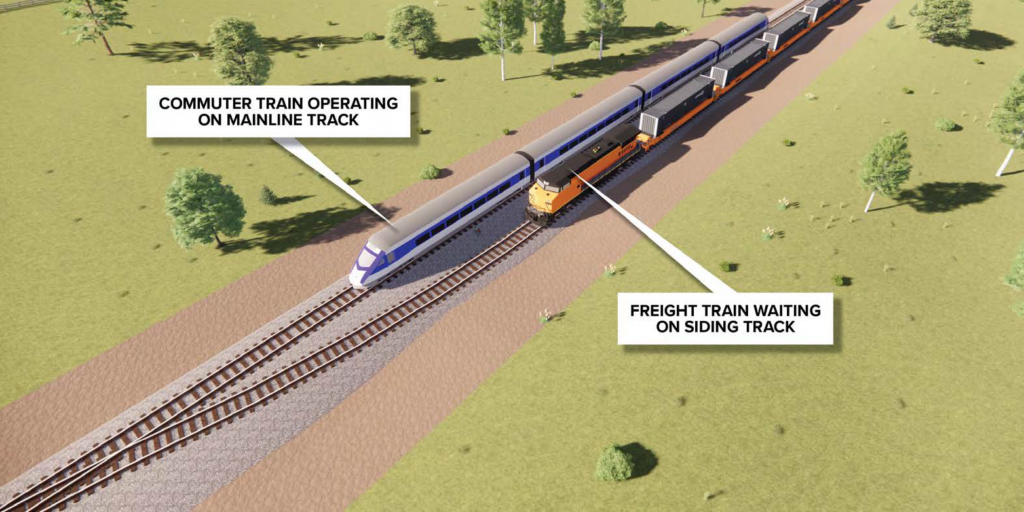

To accommodate both passenger and freight trains, the railroad is divided into operating periods, referred to as time blocks, where either BNSF or the commuter rail operator are running trains. During the 3-hour commuter rail time blocks, freight trains within the corridor would be directed to and held in one of the freight sidings until commuter services were completed. The freight train would occupy the siding while passenger trains operate on the route.

This very simplistic solution reminds us of when we were kids and had to share the train set. Child A would run their freight train for a bit and then take it of the track so child B could have a turn running their passenger train. After 3 hours, child A would then get another turn and so on…

What infrastructure upgrades are required?

The peak service calls for six new stations, equipped with 48” high-floor platforms to match those already used on RTD’s commuter rail system. These will need to built with separate sidings to allow freight trains to pass by without striking the platforms.

BNSF identified four freight passing sidings required to maintain freight rail service in the corridor. The four sidings were consolidated into three sidings with capacity to hold four freight trains to minimize roadway crossing impacts as BNSF developed its concept designs. Three freight passing sidings are required along the corridor and will be located at:.

- Between Old Wadsworth and US 36 (Westminster) – approx. 1.85 miles long

- Between Baseline Road and 55th Street (Louisville and Boulder) – approx. 4.84 miles long

- Between North 55th Street and North 63rd Street (Gunbarrel) – approx. 1.47 miles long

This joins two existing sidings located at:

- Between Nickel Street and Brainard Drive (Broomfield and Interlocken) – approx. 1.79 miles long

- Between Boulder Creek and Pearl Parkway (East Boulder) – approx. 0.73 miles long

What will the trains be like?

Five train-sets in total would be required; three to operate the service, one spare and another one undergoing maintenance.

The study concluded that the only trains readily available that could run on both RTD and BNSF infrastructure with high-floor platforms were formed of a locomotive, a regular passenger car and a cab car to enable “push-pull” operation meaning that the train would not have to be turned round or reformed at each end of the line.

The study indicated a preference for “a commonly available fleet type used by another transit agency to reduce purchase and long-term maintenance costs”. In reality this would mean partnering with an East Coast agency such as MBTA, NJ Transit, SEPTA or MTA as these are the only agencies that use high-floor FRA complaint trains in the U.S.

The study claimed that the project team could not identify a Buy America compliant, high platform compatible, self-propelled (i.e. multiple unit) train for purchase or lease) and therefore this type was ruled out. This is unfortunate as multiple unit trains are generally more efficient for trains with less than eight cars.

New Train For Colorado

It is hoped that the long term solution for rolling stock on the Northwest Rail corridor is provided by the New Train for Colorado concept which envisages a fleet of modern, fast, lightweight, highly efficient trains with superior on-board amenities connecting towns and cities all over the state.

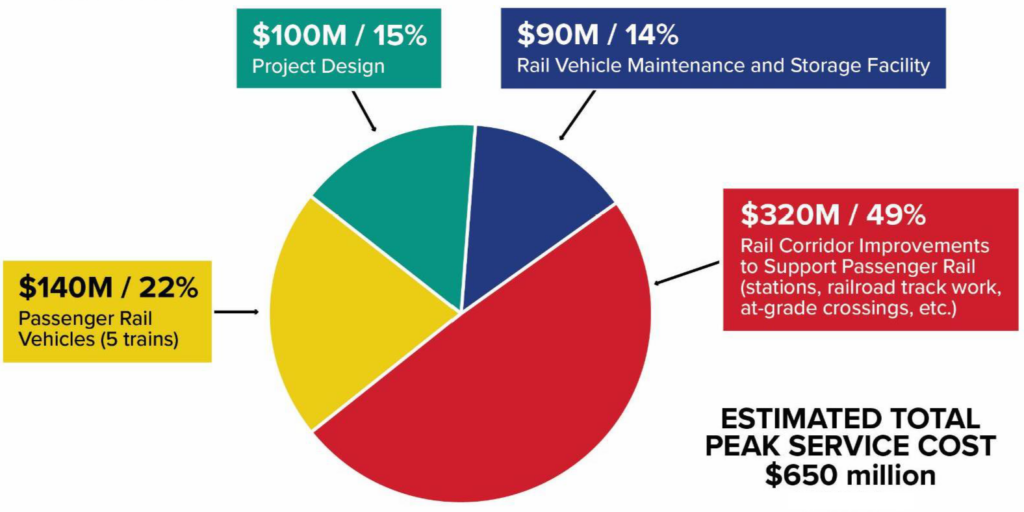

What are the anticipated costs?